Lab-Grown Diamonds

Diamond-growing technology

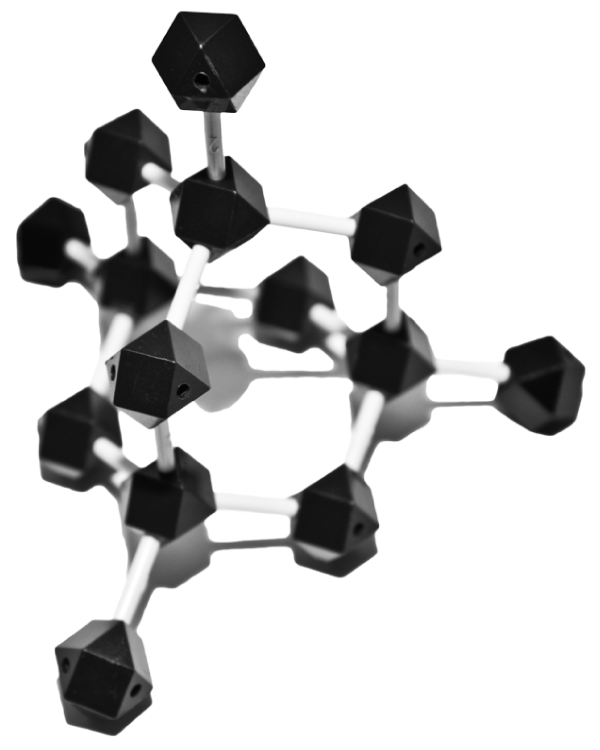

Lab-grown diamonds are generally produced by chemical vapor deposition (CVD) or high pressure high temperature (HPHT) methods.

CVD uses ultra-pure carbon-rich gases in a controlled environment. It produces Type IIa diamonds, which are quite rare in nature and account for less than two percent of all mined diamonds. Type IIa diamonds have no, or almost no, impurities; they are the purest, highest-quality diamonds.

HPHT, used since the 1950s, puts a pure, solid carbon source under high pressure and high temperature. In the presence of a catalyst, the pressurized and heated carbon crystalizes into diamond. HPHT is sometimes used to improve the color of mined or lab-grown diamonds.

Our proprietary CVD process allows us to produce stunning diamonds in color and size combinations that are seldom found in mines, such as fancy color pink diamonds that are prized for fine jewelry.

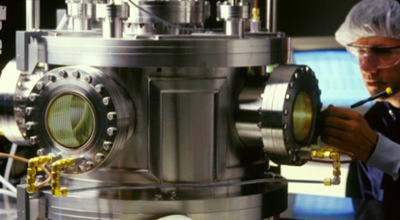

Welcome to our special growth chamber

Scio Diamond patented its CVD production process in 2003. We use tiny diamond seeds and lab-quality carbon gases in a special growing chamber. After approximately three to four weeks, the crystals have grown to significant size, typically three to five carats.

We have perfected the ability to very rigorously and accurately control the environment and the chemistry, letting us create large, high-quality single-crystal diamonds.

The precise control we exert on the process creates a scalable manufacturing platform so that we can produce large numbers of diamonds that are identical. This is important for jewelry, where consumers want matched stones in a single piece of fine jewelry.

Our highly repeatable production process is even more important to industrial customers, who need consistency and identical products time after time, a requirement that can’t be met by mined diamonds.

Lab-grown diamonds through time

-

1879

Scottish chemist James Ballantyne Hannay attempted to create diamonds by heating charcoal and iron inside a carbon crucible using a flame-heated tube.

French chemist Ferdinand Frédéric Henri Moissan repeated Hannay’s attempt, but used an electric arc furnace and rapid cooling to produce high pressure to try to transform graphite into diamond.

1893

-

1909

British chemist Sir William Crookes claimed success in synthesizing diamonds using Moissan’s technique.

American chemist Dr. J. Willard Hershey replicated Moissan’s experiment and claimed to have produced a synthetic diamond; that specimen is on display at the McPherson Museum in Kansas.

1926

-

1941

General Electric (GE), Norton and Carborundum made an agreement to create diamonds.

American physicist Percy Bridgman received the Nobel Prize in Physics for his design of high pressure anvils used for diamond research.

1946

-

1953

The first reproducible diamond synthesis using the HPHT process was reported by the ASEA (Allmänna Svenska Elektriska Aktiebolaget), one of Sweden’s major electrical manufacturing companies.

Union Carbide scientist William G. Eversole reportedly achieved vapor deposition of diamond over diamond substrate.

1953

-

1954

GE physical chemist Tracy Hall achieved the first commercially successful synthesis of diamond with a reproducible, verifiable and documented process.

Commercialization of HPHT-produced diamond grit for industrial applications.

1959

-

1968

Diamond film deposition was independently reproduced by J.C. Angus and Union Carbide coworkers.

Synthetic gem-quality diamond crystals were produced by GE.

1970

-

1985

Sumitomo Electric Industries announced production of gem-quality diamonds for industrial applications using the GE technology.

Scio Diamond predecessor, LMA, Inc. established a proprietary approach to CVD manufacturing that produces a single-crystal diamond.

1994

-

1997

LMA produced 1.5 carat diamond, believed to be the world’s largest CVD diamond.

LMA produced ¼ carat diamonds of gem-grade quality.

1998

-

2001

LMA became Apollo Diamond.

Scio Diamond predecessor, Apollo Diamond, used CVD process to create a large, pure, colorless diamond.

2005

-

2006

Industrial diamond market estimated at $1 billion.

Industry report said Scio Diamond predecessor, Apollo Diamond, was the only diamond maker with the technology to mass produce colorless stones.

2011

-

2011

Scio Diamond began operation in Greenville, SC.

US production of industrial diamond was estimated at 104 million carats, primarily grit, powder, and stone.

2013

-

2015

Scio Diamond doubled capacity of manufacturing operation.